For more than fifteen years BPDecolletage Ltd. has been manufacturing small and micro metal parts.

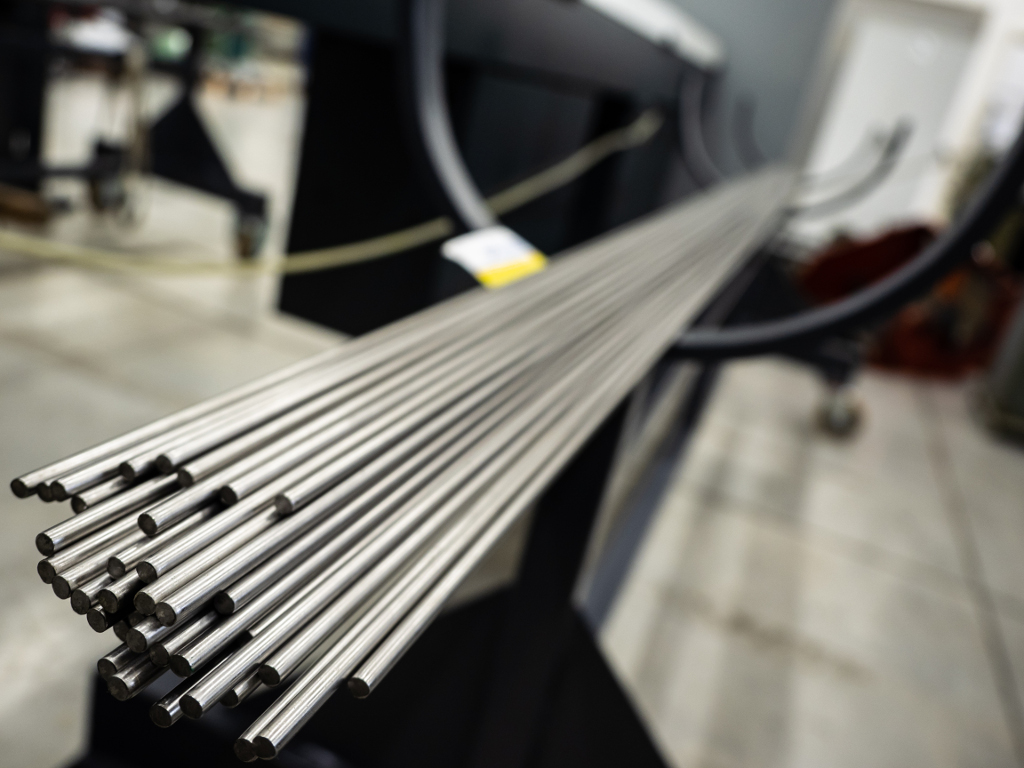

Thanks to our modern production system, we are able to both turn and mill metal parts, however, we are highly specialized in manufacturing small and micro metal parts by using either bar turning or thread cutting processes. The diameter of our products may vary in a range of 0,3 mm to 12 mm, whereas the minimum length of each single part may be longer than 0,4 mm.

The main turning technique we use is thread rolling, which is performed by ESCOMATIC lathes.

Thanks to our CNC-controlled machines, we are able to manufacture a wide range of products and each single part is refined and washed before it is sent to our customers. Besides, we perform tumbling processes on metal parts such as heat or galvanic treatments.

MACHINE INVENTORY & MATERIALS

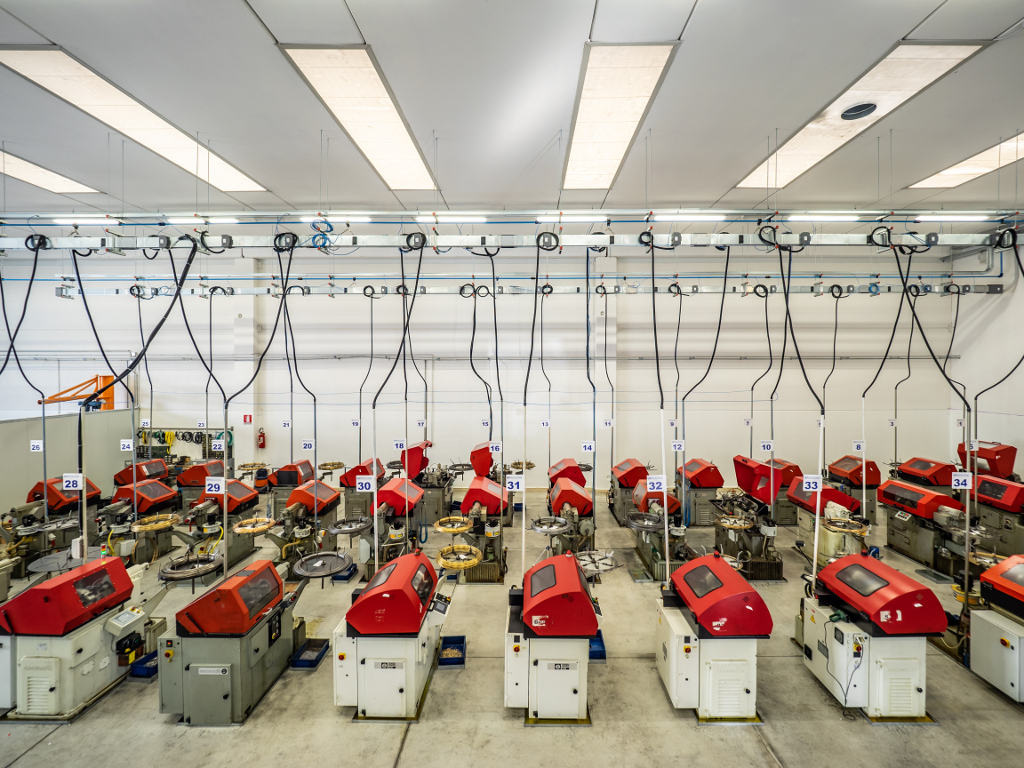

Our machinery inventory:

- 96 ESCOMATIC cam lathes

- 6 ESCOMATIC FLEX SPEED lathes

- 11 ESCOMATIC CNC-controlled lathes (New Mach)

- 10 Swiss-type 4/5/6 axes lathes

- 1 Transfer

- 1 Grinding machine

- 1 Knurling machine

Our materials: aluminum, brass, lead-free brass, bronze, steel, stainless steel, which are strictly tested and certified.

INDUSTRY 4.0

Our company has been investing in Intelligent Automation technologies in order to reduce processing waste and improve sustainability. Our lathes are actually interconnected to a server, which, in turn, is connected to the main company’s network so that the production cycle is strictly monitored by intelligent sensors and professional software.